|

Smith Brothers Services, LLC |

|

||||

| PLOW PARTS |

|

TRUCK PARTS |

|

PLOW REPAIRS |

||

|

Smith Brothers Services, LLC |

|

||||

| PLOW PARTS |

|

TRUCK PARTS |

|

PLOW REPAIRS |

||

Added 6-23-18

Kioti KB 2475 Backhoe Frame Repair and Thumb Fabrication

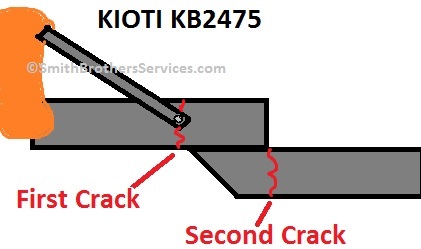

A customer brought in his Kioti KB 2475 Backhoe because the frame cracked. This was not the first time, in fact, his guys repaired it a couple of times, but it was time for it to be 'done right" (as he said), so he brought it in. They were on the right track with the repairs, but their welds were not the greatest, and they did not go far enough with the repair, all it did was allow them to find the next weak point. I will say Kioti seems to have cheapened out on this design, there is plenty of room for reinforcement where it is needed, because of the poor design it WILL need it.

The first mistake they made was using box tube, but then cutting a huge hole in it to access the nut for the support strap. They should have sleeved the hole. Really the first mistake they made was not using the 3 point hitch Top link to attach it..... IF this one cracks again I will be adding a crossmember to attach the Top Link to it. We will see if they can break it again.

The customer added angle iron on top and bottom to reinforce. It cracked in the next weak spot. Above is the right side. On the left side they only addded angle on the bottom, and it cracked in the next weak spot, and as a patch job they welded a piece of lawnmower blade over the crack, but did not weld the crack first.

Right side, crack starting on top.

This is the left side. I plated both sides and the top with 1/4" steel plate. I also added angle iron on top like they did on the other side to span the weak spot created by Kioti making the hole in the box tube for access to the strap nut.

Both sides done, plated inside, outside, and on top. You can see the piece of mower blade on the ground. I cut it off and gouged out the crack and welded it before plating. When the customer stopped by to see hwo the repairs were going, we got to talking about how he wished the machine had a thumb for moving logs, as he does a lot of tree work. So......

The start of a thumb. The jaws are made from worn out 1/2" plow cutting edge (17.5" long overall), so they are high carbon steel. I didn't really think about putting this on my site, so I did not take as many pictures as I normally would knowing I would be addding it here. The part that will be welded to the dipper is 3" channel steel. In hindsight I would have made the jaws 19" long overall.

Test fit thumb on the Kioti KB2475 dipper.

Welded on. The wire feed was stopping so you see what looks like stitch welds, the wire was twisted a little on the 44# spool, I kept opening the door and pulling some slack. The spool is almost new, so it was not easy to get slack.

All set. The thumb can be removed with two pins.

Took it outside and actually tried it out on a small Cedar stump. I pulled the stump (NOT using the thumb), then used the thumb to carry it to where I wanted to dump it..

A closer look.

Bucket curled against thumb.

Now because I am a Meyer Distributor, I have a lot of Meyer parts here. Some used, most new. I used the Rod from a 12" PA Ram that was gouged and pitted for the support, so that is why it is chrome. For the bottom mount I used a Meyer Pivot Tube and Pivot Pin. I nested the sleeve in the channel steel and welded a gusset on one side for more support. For the top mount I used an 04004 Clevis, and also for the stored position top mount. The top "bolt" is actually a 5/8" Grade 8 with a hole drilled for a hairpin. The end of the PA Ram Rod I cut off the groove and ended up with a piece I could weld to the Pivot Pin on the bottom to make a head. Then I drilled a 1/4" hole for a 1/4" Lynch Pin.

Now you may be looking for a thumb for your Kioti KB2475 Backhoe, and you can't make one like I did. As I mentioned ,there are many out there on the market. Prices are all over the place. Many are bolt on, and the main complaint I saw with them is that they move. A couple of comments said they thumb slid, and took out the hydraulic line near it. The other complaint was that the thumb did not fit properly because the dipper was too wide (so they used shims) and others it was not wide enough to fit the dipper. Make SURE you measure yours before shopping for one because there are more that will not fit than fit. I suggest you as they have many listed for sale from many different manufacturers. Some bolt on, some weld on, some are even hydraulic. The 3" channel steel I used on the Kioti KB2475 fit perfectly inside the dipper so I had the edges of the side plates to weld to.

_________________________________________________________________

Smith Brothers Services - Home Page

(973) 209-PLOW

|

Smith Brothers Services, LLC |

|

Entire site Copyright 2006 - 2018 Smith Brothers Services, LLC All Rights Reserved

Our Other Sites:

Snowplowing-Contractors.com

SmithBrothersTruckParts.com

ChucksChevyTruckPages.com

SmithBrothersPlowParts.com

MeyerST.com

MeyerPlowHelp.com MeyerPlows.info

PlowPump.info

MeyerPlowPumpParts.com

Home-Plow-By-Meyer.com

MeyerE-57.com

MeyerE-60.com

MeyerE-58H.com

MeyerDrivePro.com

MeyerLotPro.com

MeyerE-47.com

MeyerRoadPro.com

MeyerPathPro.com

MeyerVPlow.com

MeyerE-72.com Smith

Brothers Services on

YouTube

Author: Chuck Smith